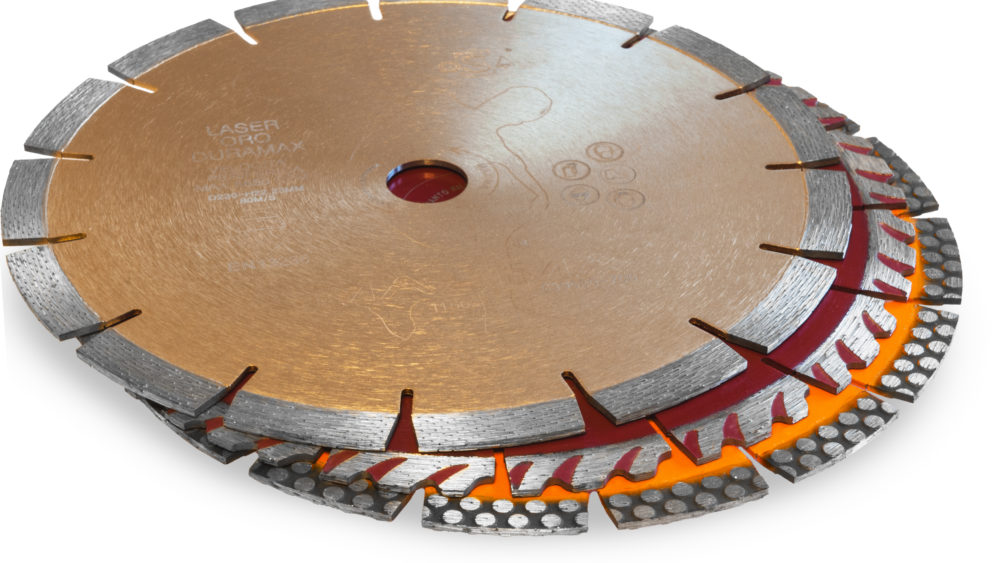

Millions of professional operators, small construction companies and general contractors’ technicians in the world are choosing laser-welded diamond blades.

Thanks to the technological evolution, especially in the productions of diamond segments and laser weldings, this type of tools can provide today higher performances than the turbo ones.

The advantages

The laser-welded diamond blades offer higher quality cutting with a better cut cleaning and speed. Their shape makes it easy to remove the excess material, while the laser welding guarantee extraordinary resistance to the high temperature during the cutting.

A universal range

Maxima presents a new universal range of laser-welded diamond blades, from diameter 115 to diameter 1000 mm, to meet the generic and specific needs of all companies and operators of the market.

These blades can be used on grinding machines, cutting machines and manual ones. Moreover, the silenced laser diamond blades reduce noise up to 30% making the cutting more comfortable.

So, high quality and safety to provide the best performance to the professional user.

Certifications and traceability

As the entire Maxima range, the new laser-welded diamond blades are certified by the oSa (European agency for diamond tools and abrasives) and according to the EN13236 regulation for the security and the laser marking of diamond tools that allows traceability after usage.

The EN13236 regulation also concerns steel cutting (which is controlled and limited) and resistance to breakage of the segments, by using specific minimal regulatory benchmarks that must be respected.